Sturdy rolls of woven wire and thick timber posts are clear components to any quality fence project. But an often-overlooked element to a successful fence installation is the staple. Properly installing quality staples will increase your fence’s durability against pressure from the outside.

The Basics

When installing your fence, it’s important that posts are placed on the outside of the containment area. (Away from the animals you are securing.) This way, when an animal leaning against the wires tests the fence, the pressure is placed primarily on the fence posts, not the staples. No matter what staples you use, a small handful of metal will never be stronger than a massive wooden post. Having your fence posts on the outside will decrease sagging and future maintenance. (Check out our blog, “Install Fence Posts on the Proper Side” to learn more about post placement.)

Why Do Staples Matter?

More than likely, the animals you are containing will cause the most wear on your fence. Outside factors, however, should still be considered. Heavy snow banks may pile against the fence line, and trees or fallen limbs might lean against the wires. There are multiple ways for a fence to be tested from the outside, and sturdy fence staples are your best defense.

The Right Staple for the Job

Out of Red Brand’s three varieties of staples, our commercially coated Barbless Fence Staples are the best option for repairs or renovating old fences. Available in multiple sizes 1″, 1-1/8″, 1 -/4″, 1-1/2″, 1-3/4″, and 2″, each shank on every staple is uniform for easier driving into older, drier, weathered posts.

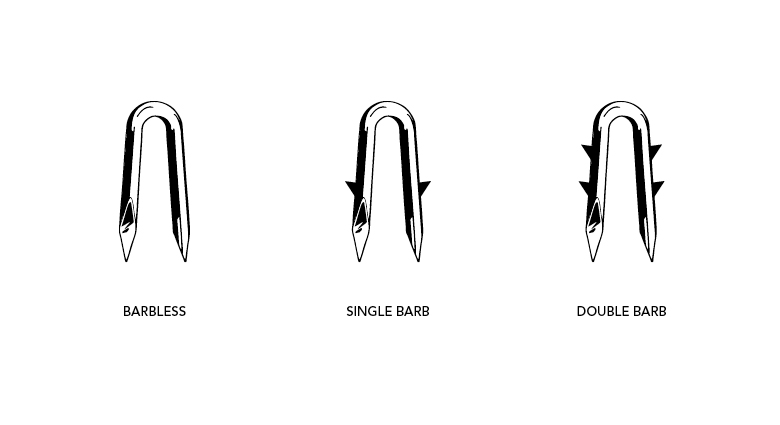

Our Galvanized staples are a good choice when installing Class 1 wire fencing. Available either barbless or with a single barb, each staple is Class 1 galvanized, making them rust-free longer. These are available from 3/4″ – 2-1/2″ in 1/4″ increments for all types of wood post.

If you anticipate your fence being tested by livestock or wildlife, corrosive elements, salt sea air, or chemically treated posts, consider Toughcoat Premium staples. These are designed for use with both Class 1 and Class 3 fence installations. Available with double barbs, and a size of up to 2-1/2″, these staples are made to penetrate deep and hold on tight. Each staple is made from eight-gauge wire, and is coated in a zinc aluminum combination that offers better protection against rust than Class 3 galvanization. All these features create a staple that meets or exceeds ASTM A856/A856M standards in quality.

Finally, for general applications, 2″ and 2-1/2″ staples are used to secure panels. Short staples are used in super dense posts like hedge and cedar, and 1-1/2″ and 1-3/4″ are used in softer treated pine post.

How to Install Staples

With the right staples, your fence will stand strong to outside pressure. To get the most out of your staples, be sure to see if your buckets of staples are right- or left-handed. Hold the staple like a “U” shape. A right-handed staple will have a cut groove on the right prong. A left-handed staple will have a groove on the left prong. (If you turn the staple over, the grooves should appear on the same side as before.)

A right-handed staple needs to be hammered in 45 degrees clockwise. This allows the prongs of the staple to spread out, giving it more grip into the post. If the same staple were driven counter-clockwise, the prongs would cross within the post, causing a less secure staple that could easily pull out.

One last bit of advice: To make sure your fence system works properly, it’s important that you do not drive staples completely into the post. The fence needs to be able to move on impact, as well as expand and contract with temperature changes.

Check out our videos, “Left-Handed & Right-Handed Staples” and “Fence Needs to Move” to learn more about staple installation.

Don’t miss a thing. Simply fill out the Subscribe form here. We’ll notify you every time we add new material. See you soon!